The leaf spring saw two major advances over time. One

was the multiple leaf design. In a multi leaf spring,

several metal springs, of varying length and thickness are

bound together. This allows for a much stronger spring,

able to carry the weight of heavier cars and trucks. The

combination of spring sizes allows for greater tuning of

the spring characteristics. For example the spring can be

soft initially but then firmer the bigger the bump or the

rate spring, as it becomes increasingly stiffer the more its

compressed.

The second development was the movable shackle. A

shackle replaces one of the fixed mounting points of the

leaf spring with one that allows movement. As the leaf

spring is flattened under compression, its attachment point

moves further out. The shackle swings allowing the leaf

to stretch. This prevents binding of the spring, increases

the suspension travel and improves ride comfort sort-off.

What it really did was extend the useful life of the leaf

spring into the new millennium-mainly on low tech trucks.

was the multiple leaf design. In a multi leaf spring,

several metal springs, of varying length and thickness are

bound together. This allows for a much stronger spring,

able to carry the weight of heavier cars and trucks. The

combination of spring sizes allows for greater tuning of

the spring characteristics. For example the spring can be

soft initially but then firmer the bigger the bump or the

rate spring, as it becomes increasingly stiffer the more its

compressed.

The second development was the movable shackle. A

shackle replaces one of the fixed mounting points of the

leaf spring with one that allows movement. As the leaf

spring is flattened under compression, its attachment point

moves further out. The shackle swings allowing the leaf

to stretch. This prevents binding of the spring, increases

the suspension travel and improves ride comfort sort-off.

What it really did was extend the useful life of the leaf

spring into the new millennium-mainly on low tech trucks.

Leaf spring

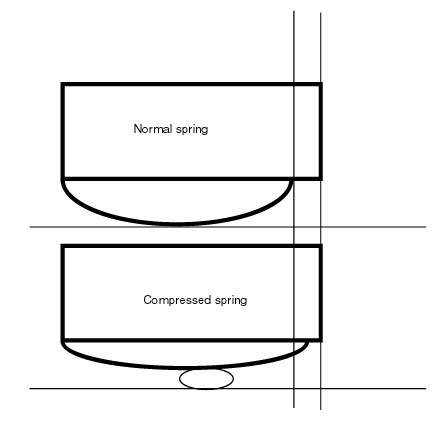

Spring compression example

Suspension Designs