There came a time in the life of the leaf spring when car

drivers decided they wanted to turn the front wheels and

change directions. Immediately following that disastrous

first turn, engineers began the quest for alternative

suspensions. Many number 2 pencils later, two new

choices arose: Coil springs and torsion springs. Both of

these would improve the ride quality and more

importantly make the cars easier to handle in turns.

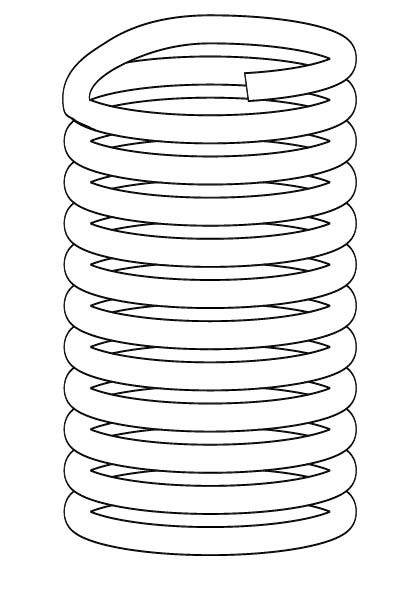

Coil Springs, are more popular, and are used on nearly

all modern cars, and many trucks. The coil spring is

exactly as the name implies a thick round bar of steel

wound into a coil. Imagine a slinky, but a very rigid

one. When a car drives over a bump the coil spring

shortens by bringing its coils closer together. When it

passes the coil extends or rebounds. A key benefit of

coil springs is that their properties are easily changed

based on thickness of the bar, number of coils and

closeness of the coils to each other and the type of steel

used. This made adjusting the suspension to make the

ride quality "just right" very easy.

As we have suggested before- leaf springs can be

adjusted also- but they are very limited in adjustment.

Leaf springs also take up a lot of real estate in the

bottom of the car. Coil springs can fit in a small area (as

small as the space taken up by a 1 liter soda bottle).

This freed engineers to place the springs where they

would work the best, not just the only place they would

fit. Specifically, out in the corners of the car, rather than

next to the frame. The wider apart the cars wheels and

suspension are, the more stable it is when turning. Also

coil springs allow for greater range of motion of the

wheel as it travels over rough roads. Coil spring's

flexibility allow cars wheels to stay in contact with very

rough roads, despite being at odd angles. Coil springs

also permit a car's wheels to 'lean' into a turn, improving

handling. Leaf springs are rigid and only permit

movement up and down.

drivers decided they wanted to turn the front wheels and

change directions. Immediately following that disastrous

first turn, engineers began the quest for alternative

suspensions. Many number 2 pencils later, two new

choices arose: Coil springs and torsion springs. Both of

these would improve the ride quality and more

importantly make the cars easier to handle in turns.

Coil Springs, are more popular, and are used on nearly

all modern cars, and many trucks. The coil spring is

exactly as the name implies a thick round bar of steel

wound into a coil. Imagine a slinky, but a very rigid

one. When a car drives over a bump the coil spring

shortens by bringing its coils closer together. When it

passes the coil extends or rebounds. A key benefit of

coil springs is that their properties are easily changed

based on thickness of the bar, number of coils and

closeness of the coils to each other and the type of steel

used. This made adjusting the suspension to make the

ride quality "just right" very easy.

As we have suggested before- leaf springs can be

adjusted also- but they are very limited in adjustment.

Leaf springs also take up a lot of real estate in the

bottom of the car. Coil springs can fit in a small area (as

small as the space taken up by a 1 liter soda bottle).

This freed engineers to place the springs where they

would work the best, not just the only place they would

fit. Specifically, out in the corners of the car, rather than

next to the frame. The wider apart the cars wheels and

suspension are, the more stable it is when turning. Also

coil springs allow for greater range of motion of the

wheel as it travels over rough roads. Coil spring's

flexibility allow cars wheels to stay in contact with very

rough roads, despite being at odd angles. Coil springs

also permit a car's wheels to 'lean' into a turn, improving

handling. Leaf springs are rigid and only permit

movement up and down.

Coil Spring

Suspension Designs