Fuel Injection

Like the carburetor, electronic fuel injection delivers a mist of

fuel into the incoming air entering the cylinder. However it

isn’t done using vacuum, its done by high pressure injection,

controlled by a computer.

Put simply, fuel injection replaces the carburetor’s fuel bowl

and metering jets with electronically controlled high pressure

nozzles that atomize fuel instantly, without the need for

engine vacuum. Fuel injectors work like the nozzle of a

spray bottle. First fuel is pumped into each fuel injector

under high pressure. Then an electronic signal is sent from a

computer to the injector telling it to spray. The tip of the

fuel injector has a tiny needle valve. When the electrical

signal reaches the injector the needle valve opens forcing the

high pressure fuel through a tiny hole-exiting as a misty

spray-perfect for combustion. The key to getting a proper

misty spray is high fuel pressure.

Fuel injection pumps fuel from the gas tank to the engine,

just like a carburetor. The difference is that fuel injection

requires the fuel to be delivered at a much higher pressure.

Carburetors can run at less than 10 psi, fuel injection

systems require at least 10 psi sometimes more than 20-30

psi. This is accomplished by a more powerful electronic fuel

pump, in or near the gas tank that pushes the fuel towards

the engine. When the fuel reaches the engine it passes

through a fuel pressure regulator, which limits ongoing fuel

pressure to a set figure. Excess fuel is then returned to the

gas tank by a return fuel line. This way only the fuel needed

to reach necessary pressure passes through the regulator and

the rest returns to the tank, stays cool and await another trip

through the pump.

There are several benefits of Fuel Injection over the

carburetor: First and foremost- fuel injection is controlled by

a computer and therefore almost infinitely adjustable for any

environmental conditions or purpose. For example, when the

temperature changes, the density of air changes as well.

When it’s colder the air is more dense-therefore more air

enters the engine, requiring more gasoline to be injected. A

fuel injection computer can make this adjustment. The

computer can measure the airflow into the engine through a

sensor (typically called the mass airflow sensor). Then the

computer adjusts the amount of fuel to match the airflow.

To review the way the fuel flow is adjusted, the computer

changes the time that the fuel injector is opened- longer for

more fuel, shorter for less.

Like the carburetor, electronic fuel injection delivers a mist of

fuel into the incoming air entering the cylinder. However it

isn’t done using vacuum, its done by high pressure injection,

controlled by a computer.

Put simply, fuel injection replaces the carburetor’s fuel bowl

and metering jets with electronically controlled high pressure

nozzles that atomize fuel instantly, without the need for

engine vacuum. Fuel injectors work like the nozzle of a

spray bottle. First fuel is pumped into each fuel injector

under high pressure. Then an electronic signal is sent from a

computer to the injector telling it to spray. The tip of the

fuel injector has a tiny needle valve. When the electrical

signal reaches the injector the needle valve opens forcing the

high pressure fuel through a tiny hole-exiting as a misty

spray-perfect for combustion. The key to getting a proper

misty spray is high fuel pressure.

Fuel injection pumps fuel from the gas tank to the engine,

just like a carburetor. The difference is that fuel injection

requires the fuel to be delivered at a much higher pressure.

Carburetors can run at less than 10 psi, fuel injection

systems require at least 10 psi sometimes more than 20-30

psi. This is accomplished by a more powerful electronic fuel

pump, in or near the gas tank that pushes the fuel towards

the engine. When the fuel reaches the engine it passes

through a fuel pressure regulator, which limits ongoing fuel

pressure to a set figure. Excess fuel is then returned to the

gas tank by a return fuel line. This way only the fuel needed

to reach necessary pressure passes through the regulator and

the rest returns to the tank, stays cool and await another trip

through the pump.

There are several benefits of Fuel Injection over the

carburetor: First and foremost- fuel injection is controlled by

a computer and therefore almost infinitely adjustable for any

environmental conditions or purpose. For example, when the

temperature changes, the density of air changes as well.

When it’s colder the air is more dense-therefore more air

enters the engine, requiring more gasoline to be injected. A

fuel injection computer can make this adjustment. The

computer can measure the airflow into the engine through a

sensor (typically called the mass airflow sensor). Then the

computer adjusts the amount of fuel to match the airflow.

To review the way the fuel flow is adjusted, the computer

changes the time that the fuel injector is opened- longer for

more fuel, shorter for less.

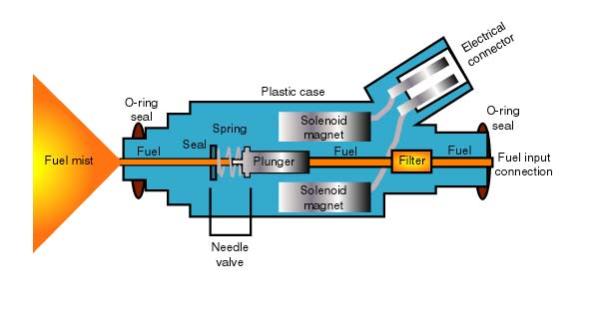

Fuel injector diagram

Fuel injection system diagram